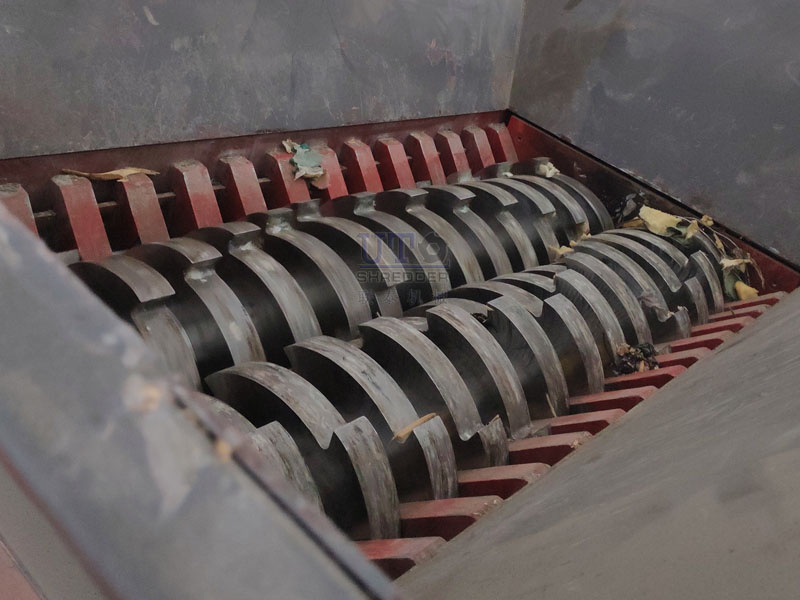

Precautions for Shredder Blade Replacement

As a wearing part, the cutter of the shredder needs

to be replaced. The cutter of the shredder is relatively expensive, so in order

to be more economical and practical, the manufacturer of the shredder

recommends that the user purchase another set of spare cutter when purchasing

the shredder equipment. When the cutter needs to be replaced, it can be

replaced directly. Then the worn shredder cutter can be used after being welded

with wear-resistant electrodes and grinded with a knife grinder, It is

economical and practical to recycle without delaying the normal operation of

the shredder

1. The alloy head of the shredder has a sharp and

sensitive edge. During the movement, installation and removal of the blade,

care must be taken to protect the alloy head from damage.

2. Regularly check the radial runout and swing of

the machine spindle to ensure that the slits of the shredder blades coincide

with each other.

3. The sundries on the spindle and flange must be

removed before the shredder blade is installed. The surface of flange plate

shall be flat and clean and perpendicular to the shaft.

4. The use of the largest flange plate can make the

saw blade run more smoothly. The size of the flange plate should be consistent.

The size of the flange plate is 1/3 of the saw blade diameter (1/2D flange

plate should be used for thin saw blades). The sawing effect is better

(especially thin blade).

5. The shredder blade shall be idle for 30 seconds

after it is installed stably, and cutting can be started after everything is

confirmed to be normal.

6. When installing the shredder blade, the flange

nut must be moderately tightened. If it is too loose, the saw blade will slip

during rotary cutting. If it is too tight, the saw blade will have internal damage

or deformation, which will affect the cutting effect.

7. Before cutting the shredder blade, the operator

must wear protective equipment (protective glasses, dust mask, helmet,

protective gloves) and check whether the protective cover of the saw is intact

CN

CN EN

EN

TEL:086-0533-3588750

TEL:086-0533-3588750 FAX:086-0533-3588750

FAX:086-0533-3588750 E-MAIL:info@utshredder.com

E-MAIL:info@utshredder.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,